Services

Comprehensive services

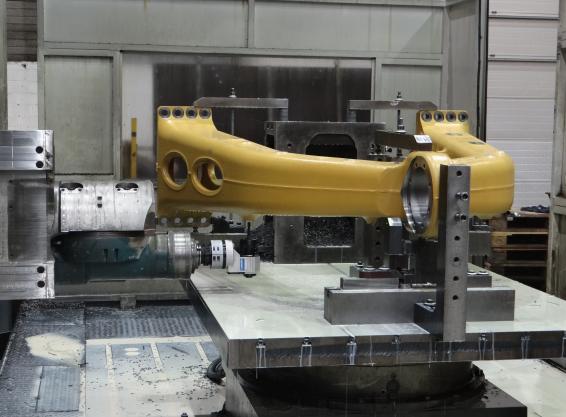

ITK can accompany you through every stage of industrialisation: project management, feasibility studies from your plans and specifications, prototyping, forge and foundry roughs approval, designing and realising machining programs, jigs and special machining tools, FAI reports, parts for pilot production approval, etc.

System supplier

From ordering the right raw materials, to finishing workpieces and assembling component modules, right up to quality control, cleaning, packing and warehousing, we provide a one-stop service covering all your needs and allowing you to focus on your core activities.

If further technologies such as hardening, chrome plating are required, we work closely with proven partner companies.

Orders on call

Our machines keep cutting while loading and unloading a workpiece. This is possible thanks to our large number of multipallet processing centers that are equipped with a multi-tool storage and with both vertical and horizontal processing options. This means that more workpieces are immediately ready for processing. This ensures that ITK is very well organized for on-demand orders for both small and large quantities.